Indlela ye-PVC ye-Calendering yaphansi iyinqubo yokukhiqiza ephumelelayo neqhubekayo, efaneleka ngokukhethekile ukukhiqizwa kwamashidi esakhiwo alinganayo futhi avumeleke (njenge-commercial homogeneous permeable flooring). Umongo wayo uwukwenza ipulasitiki ye-PVC encibilikisiwe ibe ungqimba oluncane olufana noluncane ngokusebenzisa i-multi-roll calender, bese uyipholisa ukuze ibumbe. Okulandelayo yizinyathelo ezithile kanye namaphoyinti okulawula ezobuchwepheshe abalulekile:

I. Inqubo Yekhalenda

I-Raw Material Pretreatment > Ukuxuba okushisayo okusheshisa kakhulu, ukuhlanganisa okupholisa nokubandayo, ukuxuba kwangaphakathi nokwenza ipulasitiki, ukuxuba okuvulekile kanye nokuphakela

I-4-roll calendering, i-embossing/laminating, ukupholisa nokubumba, ukunquma nokusonta

II. Isinyathelo ngesinyathelo Amaphuzu Abalulekile kanye Nemingcele Yezobuchwepheshe

1. I-Raw Material Pretreatment kanye Nokuxuba

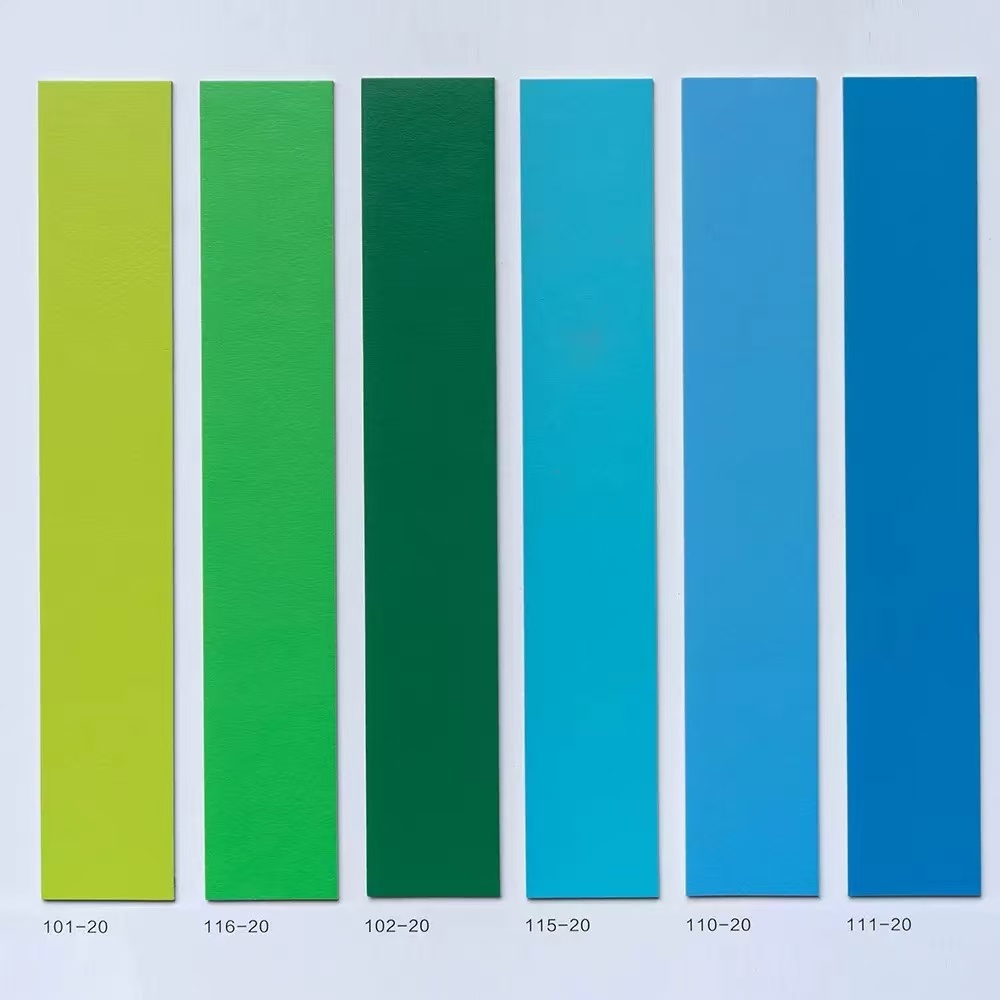

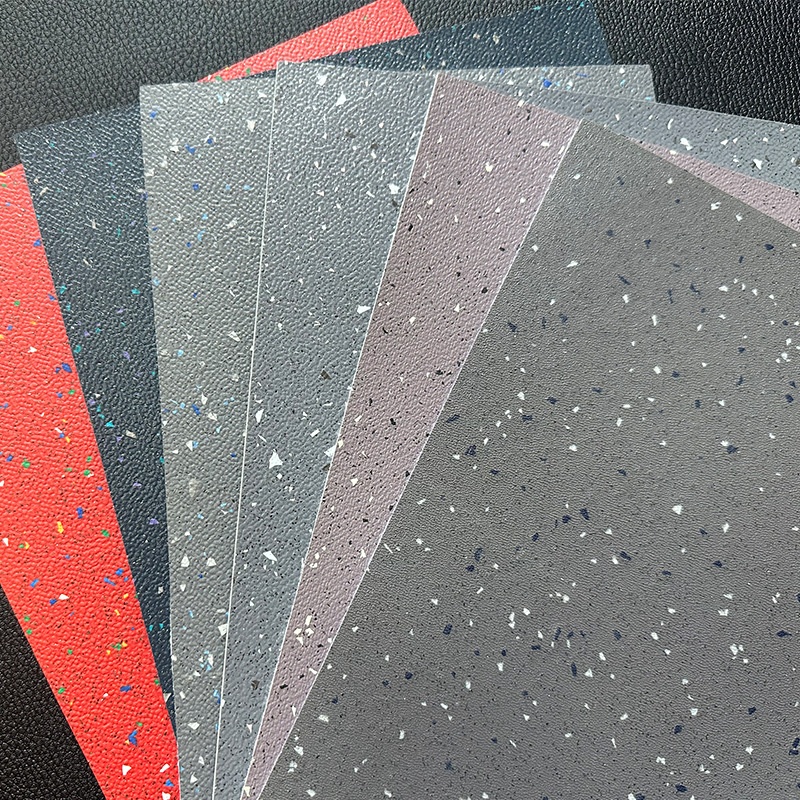

Ukubunjwa Kwefomula (Isibonelo): - I-PVC resin (uhlobo lwe-S-70) izingxenye eziyi-100, - I-Plasticizer (DINP/i-ester enobungani bemvelo) izingxenye ezingama-40-60, - I-Calcium carbonate filler (1250 mesh) izingxenye ezingama-50-80, - I-Heat stabilizer (i-calcium zinc composite, i-calcium zinc composite, izingxenye ze-Lubricant 5-1) izingxenye ze-Lubricant 3-5) - I-pigment (i-titanium dioxide/impushana yombala wezinto ezingaphili) izingxenye ezi-2-10

Inqubo Yokuxuba*:

Ukuxuba okushisayo: I-mixer yesivinini esiphezulu (≥1000 rpm), ukushisa ku-120 ° C (imizuzu engu-10-15) ukuvumela i-PVC ukuba ibambe i-plasticizer; Ukuxuba Okubandayo: Kuphole ngokushesha kuze kube ngaphansi kuka-40°C (ukuvimbela izigaxa), isikhathi sokuxuba okubandayo ≤ amaminithi angu-8.

2. Ukwenza ipulasitiki kanye nokudla

- I-Mixer Yangaphakathi: Izinga lokushisa 160-170 ° C, Ingcindezi 12-15 MPa, Isikhathi 4-6 imizuzu → Ukwakha inqwaba yerabha elinganayo;

I-Mixer evuliwe: Izinga lokushisa le-Twin-roll 165±5°C, i-Roller Gap 3-5 mm → Sika ube yimicu ukuze uphakele ikhalenda.

3. Ikhalenda ye-Four-roller (Inqubo Eyinhloko)

- Amasu Abalulekile:

- I-Roller Speed Ratio: 1#:2#:3#:4# = 1:1.1:1.05:1.0 (ukuvimbela ukuqoqwa kwezinto);

- Isinxephezelo Sobude Obuphakathi: I-Roller 2 yakhelwe ngomqhele ongu-0.02-0.05mm ukuze isuse ukuguquguquka kokugoba okushisayo. 4. Ukwelashwa Okungaphezulu Nokucwecwa

I-Embossing: I-embossing roller (i-silicone / insimbi) izinga lokushisa elingu-140-150 ° C, ingcindezi engu-0.5-1.0 MPa, isivinini esihambisana nomugqa we-calendering;

I-Substrate Lamination (Ongakukhetha): Indwangu ye-fiber yengilazi/indwangu engalukiwe, eshiswe ngaphambilini (100°C), ifakwe i-PVC incibilika ku-roller #3 ukuze kuthuthukiswe ukuzinza kwe-dimensional.

5. Ukupholisa nokuBunjwa

Izinga lokushisa lerola lokupholisa lezigaba ezintathu:

Ukulawula Ukuqina: I-Winding tension 10-15 N/mm² (ukuvikela ukushwabana okubandayo nokuguqulwa).

6. Ukunquma kanye Nokusonga

- Isilinganiso Sokuqina Kwe-Laser Online: Impendulo yesikhathi sangempela ilungisa igebe le-roller (ukunemba ± 0.01mm);

- Ukunquma Okuzenzakalelayo: Ububanzi beScrap ≤ 20mm, bugaywe kabusha futhi bufakwe i-pelletized ukuze buphinde busetshenziswe;

- Ukusonteka: Ukusonteka kwesikhungo esicindezelayo njalo, ububanzi be-roll Φ800-1200mm. III. Ubunzima Benqubo Nezixazululo

1. Ubukhulu obungalingani. Imbangela: Ukushintshashintsha kwezinga lokushisa kwerola > ±2°C. Isixazululo: I-Closed-Loop Thermal Temperature Control + Ukupholisa Kwerola Evaliwe.

2. I-Surface Gas. Imbangela: Ukuxuba Ukukhipha Igazi Okungenele. Isixazululo: Vacuum i-Internal Mixer (-0.08 MPa).

3. Imifantu yoMphetho. Imbangela: Ukupholisa Okudlulele/Ukucindezeleka Okudlulele. Isixazululo: Yehlisa I-Front-End Cooling Intensity bese Wengeza Indawo Yokupholisa Enensayo.

4. Iphethini Die. Imbangela: Ingcindezi Yerola Ye-Embossing Enganele. Isixazululo: Nyusa i-Hydraulic Pressure ibe ngu-1.2 MPa futhi Hlanza i-Roller Surface.

IV. Izinqubo Ezithuthukisiwe Zemvelo Nezokusebenza

1. Ukushintshwa Kwesinzinzisi Esingenamthofu:

- I-Calcium-Zinc Composite Stabilizer + β-Diketone Synergist → Iphumelele Ukuhlolwa Kokufuduka kwe-EN 14372;

2. Ipulasitiki Enobungani Nemvelo:

- I-DINP (i-Diisononyl Phthalate) → I-Cyclohexane 1,2-Dicarboxylate (Ecoflex®) Yehlisa I-Ecotoxicity.

3. Ukugaywa kabusha kukadoti:

- Izinsalela ezichotshozwayo → Ukuhlanganisa nokokusebenza okusha ngesilinganiso esingu-≤30% → Kusetshenziswa ekukhiqizeni ungqimba oluyisisekelo.

V. Ikhalenda vs. I-Extrusion (Ukuqhathanisa Uhlelo Lokusebenza)

Ukwakheka Komkhiqizo: Iphansi elinezimbobo ezilinganayo/Inhlanganisela yezingqimba eziningi, Ukukhishwa okuhlangene kwezingqimba eziningi (ungqimba olumelana nokugqokwa + ungqimba lwegwebu)

Ibanga Lokuqina: 1.5-4.0mm (Ukunemba ±0.1mm), 3.0-8.0mm (Ukunemba ±0.3mm)

I-Surface Finish: I-gloss ephezulu/I-Precision embossing (ukulingiswa kwezinhlamvu zokhuni), ukuthungwa kwe-Matte/Rough

Izicelo Ezijwayelekile: I-Homogeneous perforated flooring ezibhedlela nasemalabhorethri, i-SPC interlocking flooring yezindlu

Isifinyezo: Inani eliwumongo lendlela yokuhlelwa kwekhalenda lisemandleni "ukunemba okuphezulu" kanye "nokuvumelana okuphezulu"

- Izinzuzo Zenqubo:

- Ukulawula izinga lokushisa kwerola elinembile → I-coefficient yokwehluka kokuqina <1.5%;

- In-line embossing kanye lamination → Zuza itshe/metal visual effects;

- Imikhiqizo Esebenzayo:

Iphansi le-PVC elinembobo elinganayo elinezidingo zokuzinza ezinobukhulu obuphakeme (njengochungechunge lwe-Tarkett Omnisports);

- Thuthukisa Izinketho:

- Ukulawula Okukhaliphile: Ukulungiswa kwegebe le-roller elinamandla le-AI (impendulo yokuqina kwesikhathi sangempela);

- Ukubuyisela Amandla: Ukushisa kwemfucuza yamanzi okupholisa kusetshenziswa ekushiseni kwempahla eluhlaza (konga amandla angama-30%).

> Qaphela: Ekukhiqizeni kwangempela, izinga lokushisa le-calendering kanye nesivinini se-roller kufanele kulungiswe ngokuvumelana nefomula ye-fluidity (inkomba ye-mellt MFI = 3-8g / 10min) ukugwema ukuwohloka (inkomba ephuzi ΔYI <2).

Isikhathi sokuthumela: Jul-30-2025